【日光化成】多様な発想とスキルを結集させ、世の中になかった材料開発を目指す

日光化成は複数の樹脂を「ブレンド」し、新しい機能をもった材料を生み出す「材料開発メーカー」です。独自の「配合技術」=異なる原料をブレンドし、高絶縁、低誘電特性・耐薬品特性・耐熱・対静電特性などを組み合わせ、今まで世の中になかった「複合化材料」を創り出しています。

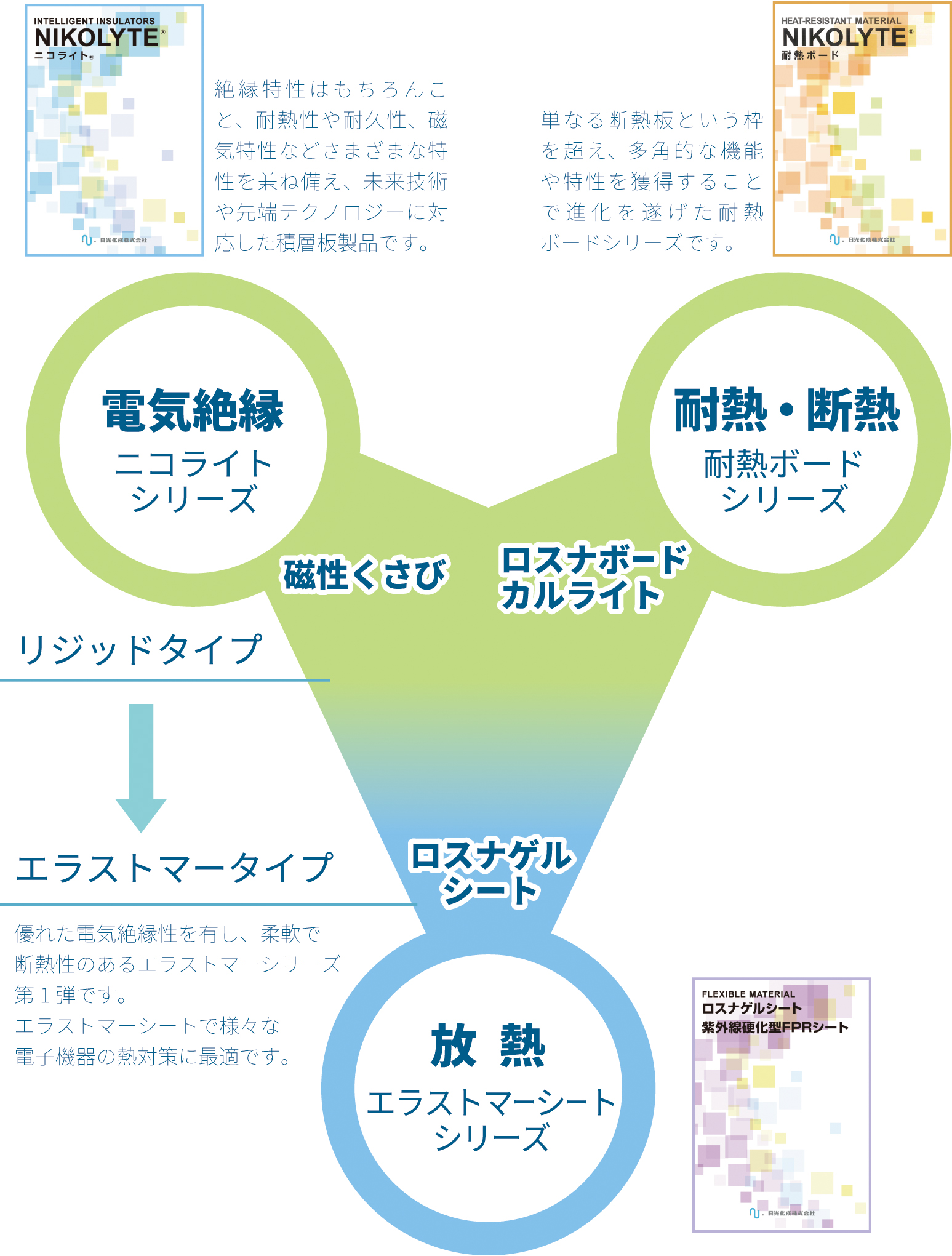

素材は新たなステージへ

我々の基礎となる電気絶縁材の技術とそれを応用した複合化材料は、ニコライト積層板からスタートし、より耐熱、断熱に優れた耐熱シリーズへと進化しました。そしてさらに、今回新シリーズとして、放熱特性に優れたエラストマーを中心とした新シリーズをリリースしました。

高温下でも卓越した断熱特性「ロスナボード」/比重1.0の超軽量耐熱・絶縁材「カルライト」

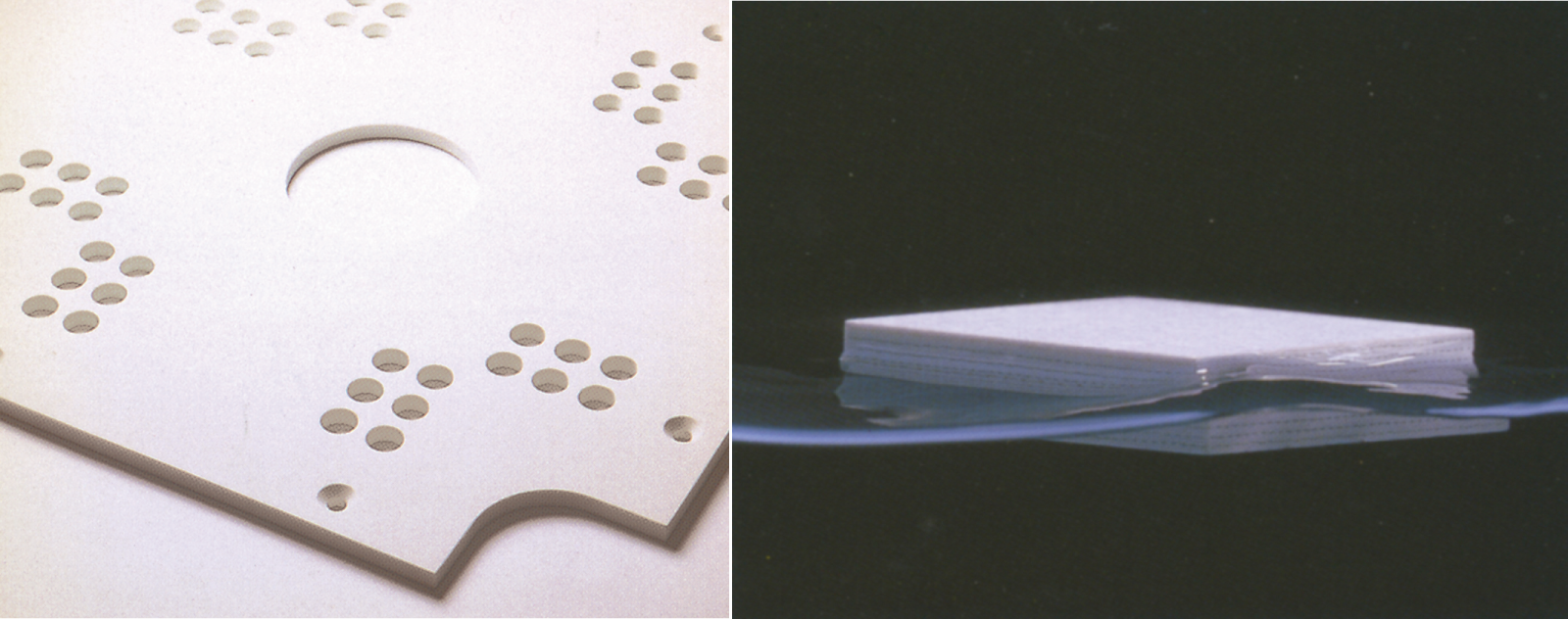

「ロスナボード」(上画像・左)

当社の耐熱ボード商品の最高グレードであり、1982年に発売されたロングセラー商品です。400度の高温の中で2万時間という過酷な条件のもとでも、形状を変えることなく、高い強度を売りにするロスナは研究開発部門の代表作品の1つで、日光化成は知らなくてもロスナボードは知っているというお声までいただくこの製品はまさに当社の原点とも言える製品です。

「カルライト」(上画像・右)

日本が誇る「技術力の結晶」である「新幹線」。車体の制御装置には、日光化成が独自に開発した「カルライト」が絶縁材料として採用されています。「カルライト」は電気特性や強度はそのままに、高速走行に適するよう重さが従来品の2分の1と軽量化されているのが特徴です

絶縁性と高透磁率を同時に実現「磁性積層板」/高い放熱性と柔軟性「ロスナゲルシート」

当社の耐熱ボード商品の最高グレードであり、1982年に発売されたロングセラー商品です。400度の高温の中で2万時間という過酷な条件のもとでも、形状を変えることなく、高い強度を売りにするロスナは研究開発部門の代表作品の1つで、日光化成は知らなくてもロスナボードは知っているというお声までいただくこの製品はまさに当社の原点とも言える製品です。

「カルライト」(上画像・右)

日本が誇る「技術力の結晶」である「新幹線」。車体の制御装置には、日光化成が独自に開発した「カルライト」が絶縁材料として採用されています。「カルライト」は電気特性や強度はそのままに、高速走行に適するよう重さが従来品の2分の1と軽量化されているのが特徴です

絶縁性と高透磁率を同時に実現「磁性積層板」/高い放熱性と柔軟性「ロスナゲルシート」

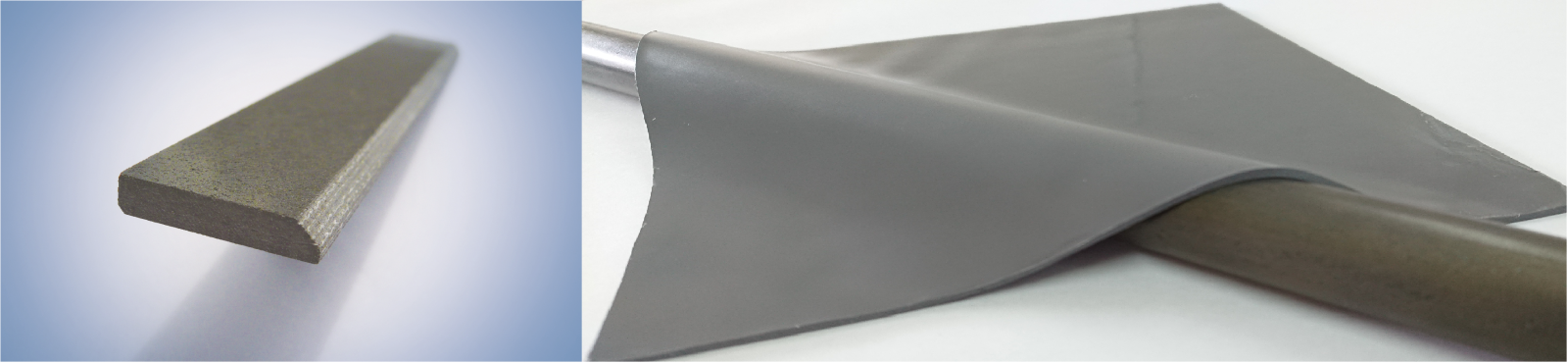

「磁性積層板」(上画像・左)

磁性積層板は日光化成が半世紀以上にわたって研究し続けてきた積層板技術を最大限に生かした、従来の絶縁材とは全く異なる高機能積層材料です。

発電機や誘導モータ等の固定子(Stator)の楔材に使用することにより高効率化によるパワーUP、省エネ、小型軽量設計が可能となります。また磁気シールド材としても使用が可能です。

「ロスナゲルシート」(上画像・右)

電子機器の高密度化・薄型化が進むと、部品から発生する熱の影響を小さくする必要があります。高いフレキシブル性を有する「ロスナゲルシート」は部品との間に置かれ、発生した熱を効果的に冷却システム(ヒートシンクなど)に伝導します。優れた電気絶縁性も有するシートで、様々な電子機器の熱対策に最適です。

当社では、上記シリーズの自社開発品に加え、 社外リソースも積極的に活用し研究開発・製品開発を行う「 オープンイノベーション」、大学の研究室を交えた「産官学コンソーシアム」などの共同開発を推進しており、日本のモノづくり技術を結集させた最先端のコンフィデンシャルな案件開発を行っています。

新しい材料を研究・開発するだけではありません。開発した材料は、その可能性を最大限に引き出すため、デザイン・加工・成形・部品化までワンストップで行っています。適正な素材をもとに「完成品」として仕上げることで、医療・自動車・車両・船舶・航空・半導体など多岐にわたる分野でのニーズに応えています。

磁性積層板は日光化成が半世紀以上にわたって研究し続けてきた積層板技術を最大限に生かした、従来の絶縁材とは全く異なる高機能積層材料です。

発電機や誘導モータ等の固定子(Stator)の楔材に使用することにより高効率化によるパワーUP、省エネ、小型軽量設計が可能となります。また磁気シールド材としても使用が可能です。

「ロスナゲルシート」(上画像・右)

電子機器の高密度化・薄型化が進むと、部品から発生する熱の影響を小さくする必要があります。高いフレキシブル性を有する「ロスナゲルシート」は部品との間に置かれ、発生した熱を効果的に冷却システム(ヒートシンクなど)に伝導します。優れた電気絶縁性も有するシートで、様々な電子機器の熱対策に最適です。

次世代のテクノロジーを創造する、新たな挑戦

当社では、上記シリーズの自社開発品に加え、 社外リソースも積極的に活用し研究開発・製品開発を行う「 オープンイノベーション」、大学の研究室を交えた「産官学コンソーシアム」などの共同開発を推進しており、日本のモノづくり技術を結集させた最先端のコンフィデンシャルな案件開発を行っています。

新しい材料を研究・開発するだけではありません。開発した材料は、その可能性を最大限に引き出すため、デザイン・加工・成形・部品化までワンストップで行っています。適正な素材をもとに「完成品」として仕上げることで、医療・自動車・車両・船舶・航空・半導体など多岐にわたる分野でのニーズに応えています。

専門機関との連携も活用し技術革新。地域社会への貢献を推進する

日光化成の開発技術を支える研究所は大阪と滋賀の2 拠点。滋賀では様々な分野の材料開発を、大阪では医療・バイオ分野の開発を担当しています。独自の基幹技術を磨きながら、各地区の工業技術センターをはじめとする公的機関や大手企業・地元大学とも連携し、高付加価値素材の開発を行っています。

そうした地域に根差した研究活動が認められ、

2018 年には経済産業省「地域未来牽引企業」、

2019 年には中小企業庁「はばたく中小企業・小規模事業者300 社」、

大阪府「大阪ものづくり優良企業賞」、

2021年には経済産業省「健康経営優良法人2021」にも選定いただきました。

今後もより地域と社会に貢献し、更なる技術革新を実現できる「未来志向型企業」を目指します。

当社へのお問合せは下記「お問合せ」ボタンよりお送りください。