[Takefu Special Steel] We provide steel materials and products that develop while inheriting the traditions of Hokuriku.

We are a unique and original manufacturer in Japan, developing our own production and sales in a wide range of fields, including materials for cutlery from household knives to industrial machine knives, industrial materials, craft materials, and others. We accept orders for a wide variety of products in small quantities and handle everything from production to sales.

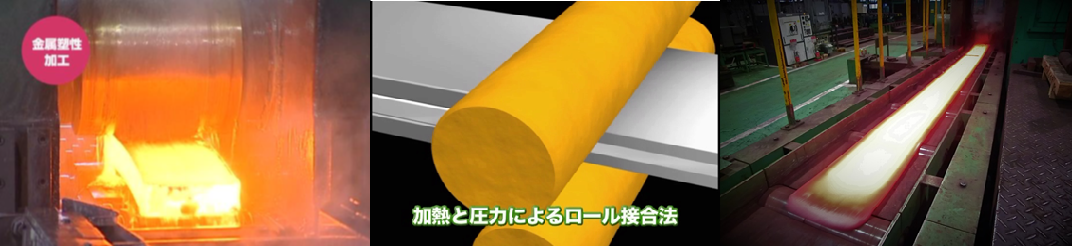

○ ○ Clad metal production

Our pride in manufacturing clad metals (metal composite materials).

Clad metals are heterogeneous metals that are joined using our unique technology to produce properties that cannot be obtained with a single metal, and can be used in a wide range of applications.

Original Cutlery Steel "V Steel Series

When you place an order with us, you can select the most suitable steel material for various applications.

Examples: V-Gold 10, Super Gold 2, Cobalt Special, etc.

The steel materials are used for a wide range of applications as follows.

Cutlery (kitchen knives, hairdressing shears, gardening shears, woodworking tools, industrial cutlery, etc.)

Industrial use (heat dissipating parts, heat retaining parts, molds, corrosion resistant parts, conductive parts, etc.)

Development of high-strength and high-toughness titanium materials

We are also developing titanium materials.

Titanium is a material with high affinity for the human body and is used in the medical field. Recently, there is a demand for miniaturization of medical instruments for use in laparoscopic surgery, which allows patients to recover quickly, and titanium must have the characteristics to withstand miniaturization. Generally, alloying elements such as rare metals are added to titanium to increase its strength, but on the other hand, high-strength and high-toughness materials using only elements harmless to the human body have been sought.

We have developed a material with both elongation and strength by using a powder hardening method instead of the common melting method, and by blending only elements that are harmless to the human body, such as oxygen and nitrogen. Furthermore, by utilizing our rolling technology, we are able to produce a material that is even denser and stronger than titanium alloys.

Clad metals are heterogeneous metals that are joined using our unique technology to produce properties that cannot be obtained with a single metal, and can be used in a wide range of applications.

Original Cutlery Steel "V Steel Series

When you place an order with us, you can select the most suitable steel material for various applications.

Examples: V-Gold 10, Super Gold 2, Cobalt Special, etc.

The steel materials are used for a wide range of applications as follows.

Cutlery (kitchen knives, hairdressing shears, gardening shears, woodworking tools, industrial cutlery, etc.)

Industrial use (heat dissipating parts, heat retaining parts, molds, corrosion resistant parts, conductive parts, etc.)

Development of high-strength and high-toughness titanium materials

We are also developing titanium materials.

Titanium is a material with high affinity for the human body and is used in the medical field. Recently, there is a demand for miniaturization of medical instruments for use in laparoscopic surgery, which allows patients to recover quickly, and titanium must have the characteristics to withstand miniaturization. Generally, alloying elements such as rare metals are added to titanium to increase its strength, but on the other hand, high-strength and high-toughness materials using only elements harmless to the human body have been sought.

We have developed a material with both elongation and strength by using a powder hardening method instead of the common melting method, and by blending only elements that are harmless to the human body, such as oxygen and nitrogen. Furthermore, by utilizing our rolling technology, we are able to produce a material that is even denser and stronger than titanium alloys.

Echizen Brand Products Consortium (iiZA)

We have established a local brand " Echizen Brand Products Consortium (iiZA )" in cooperation with craftsmen of Echizen hammered cutlery production area. We are involved in external sales activities as the secretariat of the Consortium.

The iiZA kitchen knife series consists of three types of knives made of different grad metals.

We have established a local brand " Echizen Brand Products Consortium (iiZA )" in cooperation with craftsmen of Echizen hammered cutlery production area. We are involved in external sales activities as the secretariat of the Consortium.

The iiZA kitchen knife series consists of three types of knives made of different grad metals.

1110 Series (immediate above image, left): VG10 stainless triple-layer steel blade

The blade structure of the 1110 series is a three-layer structure with rust-resistant and rigid stainless steel on both sides and VG10 stainless steel blade steel in the center.

The beautiful wave pattern that appears on the blade edge indicates that it is a three-layer steel blade. This three-layer structure is characterized by "no breakage and no bending," which is based on traditional Japanese sword manufacturing techniques.

Both sides are made of stainless steel, which is more resistant to rust and corrosion.

1210 Series (middle image above): VG10 multi-layer triple-layer steel blades

The blade structure of the 1210 series is a three-layer structure consisting of 33 alternating layers of low carbon stainless steel (soft) and high carbon stainless steel (hard) base metal on both sides of a VG10 stainless steel blade steel center.

Forging these layers produces an elegant and brilliant pattern called Damascus pattern. This pattern is created by the handiwork of craftsmen who forge by random strikes, and no two pieces are alike. The multi-layered sandwiching of the Damascus pattern adds even more toughness than stainless steel three-layers.

1310 Series (upper right ): New material: Coreless multi-layer steel blade

The blade steel of the 1310 series is a revolutionary material made by combining two coreless steels: VG10 and VG2. 70 layers of high-grade stainless steel blade steel are stacked and forged, resulting in a fine metallic structure that is more resilient and less prone to breakage than a single layer of steel. The exquisite forging also achieves an unparalleled sharpness that is unparalleled. The beautifully detailed ripple pattern that appears on the entire surface of the blade is proof of the harmony of forging and material technology created by the skill of each and every craftsman.

The blade structure of the 1110 series is a three-layer structure with rust-resistant and rigid stainless steel on both sides and VG10 stainless steel blade steel in the center.

The beautiful wave pattern that appears on the blade edge indicates that it is a three-layer steel blade. This three-layer structure is characterized by "no breakage and no bending," which is based on traditional Japanese sword manufacturing techniques.

Both sides are made of stainless steel, which is more resistant to rust and corrosion.

1210 Series (middle image above): VG10 multi-layer triple-layer steel blades

The blade structure of the 1210 series is a three-layer structure consisting of 33 alternating layers of low carbon stainless steel (soft) and high carbon stainless steel (hard) base metal on both sides of a VG10 stainless steel blade steel center.

Forging these layers produces an elegant and brilliant pattern called Damascus pattern. This pattern is created by the handiwork of craftsmen who forge by random strikes, and no two pieces are alike. The multi-layered sandwiching of the Damascus pattern adds even more toughness than stainless steel three-layers.

1310 Series (upper right ): New material: Coreless multi-layer steel blade

The blade steel of the 1310 series is a revolutionary material made by combining two coreless steels: VG10 and VG2. 70 layers of high-grade stainless steel blade steel are stacked and forged, resulting in a fine metallic structure that is more resilient and less prone to breakage than a single layer of steel. The exquisite forging also achieves an unparalleled sharpness that is unparalleled. The beautifully detailed ripple pattern that appears on the entire surface of the blade is proof of the harmony of forging and material technology created by the skill of each and every craftsman.

○Others

In addition to the above, we are also involved in many other businesses, including contract metal processing (hot and cold rolling, heat treatment, etc.) and contract sales of brand-name kitchen knives.

[Examples of problem solving using our products and materials].

(1) Harvesting blade material

For a vegetable harvesting equipment manufacturer looking for a cutting blade with improved long-lasting sharpness and corrosion resistance, we proposed our material for a comparative test. We installed our material in the same equipment as the conventional product and conducted cutting tests several thousand times. The results showed that the sharpness of our material did not deteriorate, and its corrosion resistance was better than that of the conventional product.

(2) Carpenter's tools

In the past, customers used powdered HSS for planing, but it was difficult to forge and weld at the customer's site because of its hardness and poor workability. Our cladding technology made it possible to join steel and HSS, which is inherently difficult. In addition, the workability was improved and the cost was reduced by using expensive materials only for the steel part.

(3) Blades for crushing agricultural products

The harsh environment in which agricultural products are crushed with soil and stones mixed in during harvesting, and the use of conventional blades made of steel alone had problems such as cracking and chipping that would stop work at the plant if the blades were subjected to impact. The use of 3-layer cladding has improved the impact resistance of the outer part of the blade, making it possible to produce a blade that can withstand continuous operation for many months. In addition, a well-balanced grinding effect is also apparent during continuous use, and the blades are used while maintaining their sharpness.

(4) Blades for agricultural machinery

In various applications, such as lawn mowing and grass cutting, agricultural blades are used with rotating threaded blades. However, all-steel or brazed blades are sometimes unable to correct cracks or angles during the threading process. Clad materials made of soft steel and steel bonded together can now be used to produce blades that can withstand strong processing and still have high quality.

(5) Shaving blades for leather products

Clad materials are used for shaving blades, which are used to shave the flesh side of tanned hides with a rotating roller blade in order to adjust the thickness of the hides according to their grade before dyeing, greasing, and other water-based operations. A long spiral blade is attached to the base roll, and by cladding the blade, it can be used in a flexible state without breaking or bending.

If you are interested in Takefu Special Steel's products and materials, please contact us using the form below.

In addition to the above, we are also involved in many other businesses, including contract metal processing (hot and cold rolling, heat treatment, etc.) and contract sales of brand-name kitchen knives.

[Examples of problem solving using our products and materials].

(1) Harvesting blade material

For a vegetable harvesting equipment manufacturer looking for a cutting blade with improved long-lasting sharpness and corrosion resistance, we proposed our material for a comparative test. We installed our material in the same equipment as the conventional product and conducted cutting tests several thousand times. The results showed that the sharpness of our material did not deteriorate, and its corrosion resistance was better than that of the conventional product.

(2) Carpenter's tools

In the past, customers used powdered HSS for planing, but it was difficult to forge and weld at the customer's site because of its hardness and poor workability. Our cladding technology made it possible to join steel and HSS, which is inherently difficult. In addition, the workability was improved and the cost was reduced by using expensive materials only for the steel part.

(3) Blades for crushing agricultural products

The harsh environment in which agricultural products are crushed with soil and stones mixed in during harvesting, and the use of conventional blades made of steel alone had problems such as cracking and chipping that would stop work at the plant if the blades were subjected to impact. The use of 3-layer cladding has improved the impact resistance of the outer part of the blade, making it possible to produce a blade that can withstand continuous operation for many months. In addition, a well-balanced grinding effect is also apparent during continuous use, and the blades are used while maintaining their sharpness.

(4) Blades for agricultural machinery

In various applications, such as lawn mowing and grass cutting, agricultural blades are used with rotating threaded blades. However, all-steel or brazed blades are sometimes unable to correct cracks or angles during the threading process. Clad materials made of soft steel and steel bonded together can now be used to produce blades that can withstand strong processing and still have high quality.

(5) Shaving blades for leather products

Clad materials are used for shaving blades, which are used to shave the flesh side of tanned hides with a rotating roller blade in order to adjust the thickness of the hides according to their grade before dyeing, greasing, and other water-based operations. A long spiral blade is attached to the base roll, and by cladding the blade, it can be used in a flexible state without breaking or bending.

If you are interested in Takefu Special Steel's products and materials, please contact us using the form below.