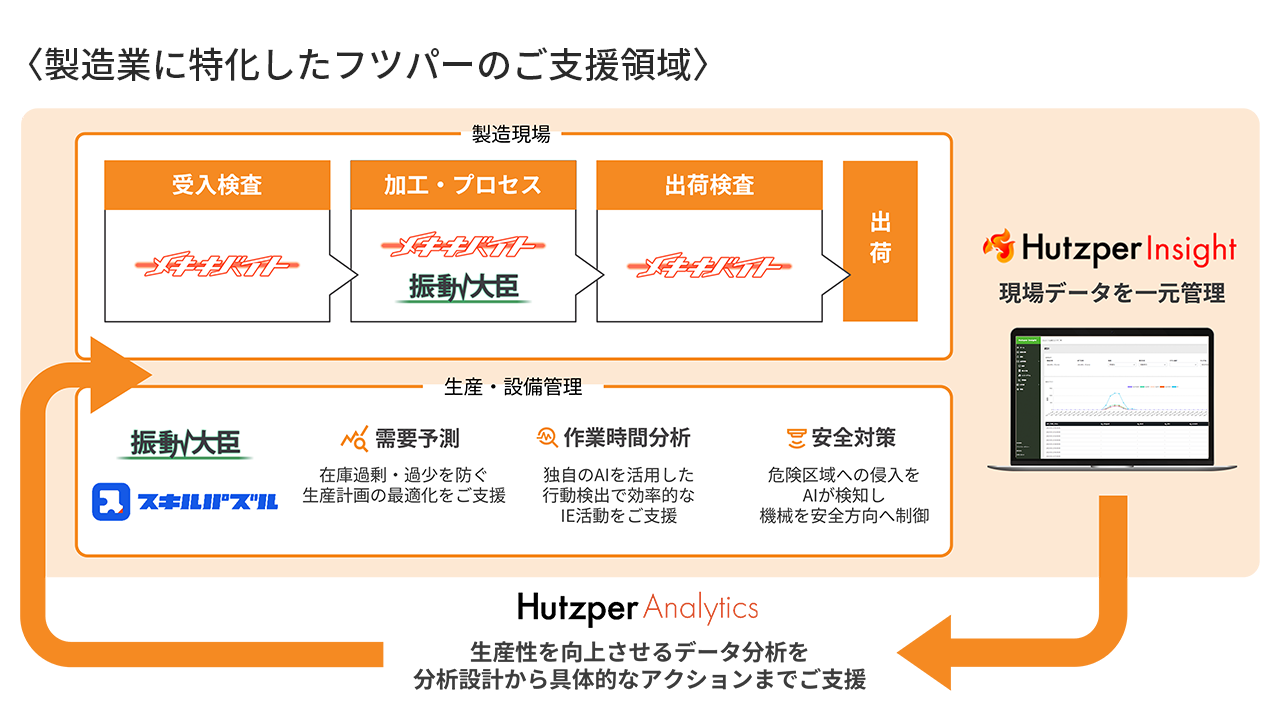

[Hutzper] Really useful in the field! AI Services for the Manufacturing Industry

With the mission of "making the latest technology a reliable workforce," we offer AI as a truly useful tool in the field, not a magical AI that is just a pipe dream.

We offer AI that is not a magical dream, but a tool that is truly useful in the field, with a price that allows for a quick return on investment, ease of implementation, and above all, accuracy. We also support smart factories with our tailor-made original AI, including the following three package services.

1. Mekikibyte, a visual inspection and quality improvement AI for the manufacturing industry

2. Equipment maintenance IoT "Vibration Minister

3. Staffing optimization AI "Skill Puzzle

Mekikibyte, a High-Precision Visual Inspection AI Solution that Replaces Visual Inspection

We provide high-precision AI at a low price by developing a unique and highly efficient algorithm, which would normally be expensive. It realizes quantitative evaluation of visual inspection, which was impossible in the past, and supports quality improvement activities based on numerical values!

[Problem to be solved]

The following issues in visual inspection in the manufacturing industry

Insufficient manpower / Difficulty in training

Unstable inspection accuracy

Difficulty in automation (false positives, difficulty in setting rules, inspection accuracy, etc.)

Return on investment/expensive investment

[Strengths of Hutzper]

High-precision AI

Stable and highly accurate detection of defects that are difficult to distinguish by conventional image processing

Total support by professional engineers

Integrated support system from introduction consultation to operation, including hardware design

Low Cost

Low-cost, high-precision AI is offered at a low price, which would normally be expensive! Early return on investment is possible.

Quality Improvement

Unique high quality control function that leads to root cause of defects

We provide high-precision AI at a low price by developing a unique and highly efficient algorithm, which would normally be expensive. It realizes quantitative evaluation of visual inspection, which was impossible in the past, and supports quality improvement activities based on numerical values!

[Problem to be solved]

The following issues in visual inspection in the manufacturing industry

Insufficient manpower / Difficulty in training

Unstable inspection accuracy

Difficulty in automation (false positives, difficulty in setting rules, inspection accuracy, etc.)

Return on investment/expensive investment

[Strengths of Hutzper]

High-precision AI

Stable and highly accurate detection of defects that are difficult to distinguish by conventional image processing

Total support by professional engineers

Integrated support system from introduction consultation to operation, including hardware design

Low Cost

Low-cost, high-precision AI is offered at a low price, which would normally be expensive! Early return on investment is possible.

Quality Improvement

Unique high quality control function that leads to root cause of defects

Equipment Maintenance IoT Solution "Vibration Minister" Leads to Equipment Maintenance and Productivity Improvement

Unlike AI companies' proprietary products, this practical IoT solution, developed jointly with a company, incorporates "voices from the field" and contributes to improved production efficiency and promotion of technology transfer.

It records the know-how of skilled workers in the form of data, standardizes equipment maintenance, and makes your company's technology a valuable asset by extracting various types of data.

[Issues that can be solved]

Shortage of personnel / Difficulty in training successors

Difficulty in handing down the sensory know-how of skilled workers

Variation in judgment criteria and indicators

Enormous amount of inspection work

Excessive burden on workers

[Advantages of Hutzper]

Data conversion by acquiring vibration values

By analyzing the acquired vibration values using a proprietary algorithm, the operating conditions of various types of equipment can be quantified. Trend analysis is also possible from automatically stored values.

Labor saving by IoT

Data from each piece of equipment is centrally managed and displayed in the monitoring room at once. Real-time notification of abnormalities and, if necessary, control of machinery in the direction of safety are also possible.

Kaizen activities for the entire process by linking with our service "Hutper Insight

Causal relationship analysis with other on-site data (manufacturing parameters, inspection results, etc.) enables optimization and kaizen of the entire process.

Unlike AI companies' proprietary products, this practical IoT solution, developed jointly with a company, incorporates "voices from the field" and contributes to improved production efficiency and promotion of technology transfer.

It records the know-how of skilled workers in the form of data, standardizes equipment maintenance, and makes your company's technology a valuable asset by extracting various types of data.

[Issues that can be solved]

Shortage of personnel / Difficulty in training successors

Difficulty in handing down the sensory know-how of skilled workers

Variation in judgment criteria and indicators

Enormous amount of inspection work

Excessive burden on workers

[Advantages of Hutzper]

Data conversion by acquiring vibration values

By analyzing the acquired vibration values using a proprietary algorithm, the operating conditions of various types of equipment can be quantified. Trend analysis is also possible from automatically stored values.

Labor saving by IoT

Data from each piece of equipment is centrally managed and displayed in the monitoring room at once. Real-time notification of abnormalities and, if necessary, control of machinery in the direction of safety are also possible.

Kaizen activities for the entire process by linking with our service "Hutper Insight

Causal relationship analysis with other on-site data (manufacturing parameters, inspection results, etc.) enables optimization and kaizen of the entire process.

Skill Puzzle" AI for Optimizing Staffing

AI suggests optimal staffing by inputting man-hours, skills, and work status. It can handle time-consuming shift creation and sudden reassignments, as well as shift assignments in line with training plans. De-formatting is achieved through more effective use of the competence management chart.

[Problems that can be solved]

Time and man-hours are required to create shifts.

Shifts tend to prioritize current conditions over training plans.

It is difficult to reassign workers when production plans or attendance changes.

It is difficult to reassign workers when production plans or work statuses change.

[Hutzper's Strengths]

Management menu specialized for the manufacturing industry

Shifts can be created according to production process and skill level

Skill management function based on competence management chart

Enables planning of individual skills and visualization of current status, de-formatting the competence management chart, and contributes to the development of multi-skilled workers, improved engagement, and support for personnel evaluation.

AI suggests optimal staffing by inputting man-hours, skills, and work status. It can handle time-consuming shift creation and sudden reassignments, as well as shift assignments in line with training plans. De-formatting is achieved through more effective use of the competence management chart.

[Problems that can be solved]

Time and man-hours are required to create shifts.

Shifts tend to prioritize current conditions over training plans.

It is difficult to reassign workers when production plans or attendance changes.

It is difficult to reassign workers when production plans or work statuses change.

[Hutzper's Strengths]

Management menu specialized for the manufacturing industry

Shifts can be created according to production process and skill level

Skill management function based on competence management chart

Enables planning of individual skills and visualization of current status, de-formatting the competence management chart, and contributes to the development of multi-skilled workers, improved engagement, and support for personnel evaluation.

With the above three solutions at the core, we support the optimization of the entire factory and the creation of a smart factory using AI technology and onsite expertise in manufacturing processes, production and equipment management, etc!

As a DX partner, we will accompany you from the identification of your priority issues to specific actions.

For product details and document download, please visit our website at

https://hutzper.com/

As a DX partner, we will accompany you from the identification of your priority issues to specific actions.

For product details and document download, please visit our website at

https://hutzper.com/